A weekly blog series by John Carroll, Associate Managing Director, Regulatory Compliance

************************************

Every year I make it a point to post several articles about the mandatory requirements of response equipment under the Oil Pollution Act of 1990 (OPA90) and the options to comply accordingly for regulated operations. As many in industry outsource this function, much of these conversations are around Oil Spill Removal Organizations (OSRO) and which ones should be utilized.

COVID-19 is offering some interesting trends. As of late we’re getting many requests from our clients to update their OSROs within their response plans. At first, we chalked it up to new year housekeeping; however, as time has progressed, we’ve begun to see it a bit differently.

- With oil prices down, companies are looking to renegotiate contracts for lower rates.

- The slowing economy has caused several OSROs around the U.S. to shutter locations, and in some extreme cases, close their doors for good.

- Companies seeking to save money are bringing outsourced services indoors.

- USCG Requirements

- PHMSA Requirements

- EPA Requirements

With so much changes happening in the Energy sector now it can be hard to recall what is required to be in place when changes are made. Today’s article looks to offer some guidance for those in the processes of changing their OSRO.

At face value this appears to be a relatively easy action given there are a lot of OSROs in the U.S. from which to choose. However, under OPA90, operators of pipelines and facilities are required to secure by contract OSROs that meet certain levels of classifications; we’ll get into that in more detail below. As such, this can significantly narrow the playing field.

Under OPA90, the Pipeline and Hazardous Materials Safety Administration (PHMSA), the Environmental Protection Agency (EPA), and the United States Coast Guard (USCG) note in their rules what is required of operators in the way of response equipment for different tiered events; e.g., 1-hour, 2-hour, etc. However, each rule is slightly different:

Are all OSROs created equal?

To be clear, I am not stating some companies are better than others, but companies do vary greatly in terms of where they are located, what type of equipment they have, what they are trained to do and what environments they are prepared for.

How does one go about securing an OSRO and ensuring they meet the necessary requirements?

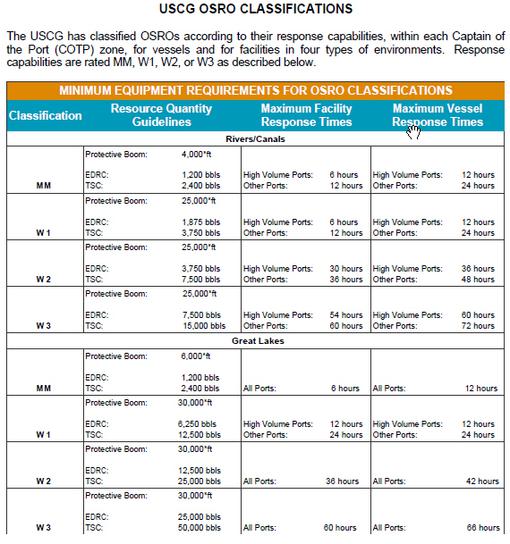

Initially, there is no wrong or right way. Begin by asking companies around you who they are using. Search on Google; use Cleanup Oil using the link below, call your current OSRO and see if they cover the area or know anyone that does. Once you have located an OSRO that might suit your needs, use the USCG OSRO classification workbook (see below) to view their rating for the area. What are ratings? The chart below is an example of how the USCG rates OSROs. In addition to the two below, there are Inland, Nearshore, Offshore and Open Ocean ratings. Ratings are based on the environment in which a spill may occur, i.e., your location.

If your OSRO is listed, and properly rated based on the needs as noted in the agency reference links above, you’re good to go. Next, secure a contract and insert a copy of the contract into your plan; you’ve now checked off that box.

My OSRO isn’t listed in my area in the USCG’s list of OSROs. Now what?

This happens often. What usually occurs is a company will have a contract with X company for the majority of their assets. After building or acquiring a new asset, they will try to extend their existing OSRO contract to the new asset. However, the OSRO is not listed or properly rated for the area in the USCG’s list of OSROs. When this happens, call your current or proposed OSRO and share this information and the requirements based on the applicable agency from above to see if they can meet this through network contracts or other means. If no, that is a different dilemma. See the next question.

My OSRO isn’t listed in the USCG’s list of OSROs. Now what?

Under OPA90, operators are required to adhere to the National Preparedness for Response Exercise Program (PREP) unless an alternative is approved; no one files for this. That said, if one can’t find an OSRO that is certified/approved by the USCG, then one must ensure their contractor is adhering to PREP themselves, in addition to possibly acquiring one’s own equipment to fill in the required planning/responding requirements under OPA90, i.e., 1,000’ of boom in one-hour at an EPA regulated facility.

When selecting a non-classified USCG OSRO, you will be required to maintain an inventory of their equipment as it pertains to your needs, proof of their relevant employee training and proof of their PREP exercises in your plan. Since an OSRO is approved by the USCG, the USCG has done the background work for you, thus removing these requirements from the operator. Maintaining these records can be a heavy burden to keep up with, as keeping up with third party records is never an easy task – it’s hard enough in-house. Unfortunately, though, in some remote areas of the U.S., this is the only option due to a lack of USCG classified OSROs. In these cases, one must manage and ensure all planning requirements are addressed in addition to annual paperwork documentation.

Ultimately, choose one that can meet the timing requirements, equipment ratings for the area, and that has a good overall reputation. You do not want to be inspected or be part of a Government‐Initiated Unannounced Exercise (GIUE) and to be found lacking proper coverage; or worse yet, when the actual event does happen, learn your OSRO is woefully under qualified.

Additional Reference Articles

- Deciphering what OSRO is needed for your OPA90 plan.

- Non-USCG Classified OSRO vs. Classified-USCG OSRO (OPA90 Discussion)

- One-Hour and Two-Hour Equipment Needs under EPA’s OPA90 Rule

- How Much Boom Do I Need? (OPA90 Discussion)

- Am I Required to use ICS at my Facility? (OPA90 Discussion)

- Did you know the National Preparedness for Response Exercise Program (PREP) Guidelines were updated?

John is a compliance specialist whose vast industry experience (Valero, ExxonMobil, Shell, Kinder Morgan, Chevron, ConocoPhillips, NuStar Energy, Philips 66, NRG, Enterprise, Cemex, Conagra to name only a few) and deep technical knowledge make him indispensable. For environmental compliance planning, development, training, QA/QC and auditing he is an industry authority without equal.

With such skills and leadership expertise, John aids all kinds of industry and government clients who must comply with increasingly stringent environmental regulations. He also works as an intermediary with enforcement agencies guiding clients through compliance and helping to resolve violations.

John leads Witt O’Brien’s in-house permitting and compliance planning programs, including training, development and final deliverables. He also manages our soil, air and water monitoring and testing programs.